About

With over 25 years’ experience, we have developed solutions for some of the most challenging products.

It is not enough to “leave well enough alone.” The “one size fits all” solution is inefficient and unreliable, resulting in low counts and lost production.

We employ the latest in Computer Aided Engineering and manufacturing, Our material is exclusively selected for consistency and stability.

Design & Quality

Our engineering staff and product specialists evaluate each customer’s materials and components to select the best machine for the job. Where necessary, changes to our standard machines will be made to ensure customer satisfaction. Only the best materials are used to fabricate our machines. Strict inspection of all raw materials is carried out before being used on our equipment.

Service

Highly trained specialists ensure that the assembly, programming and control systems meet the high standards demanded by IPS. No machine leaves the factory before passing all operational requirements. IPS maintains a highly trained service force available within 24 hours for all your training and service needs. IPS stands behind every machine and part we sell, helping you to maintain your packaging equipment.

Trust & Reliability

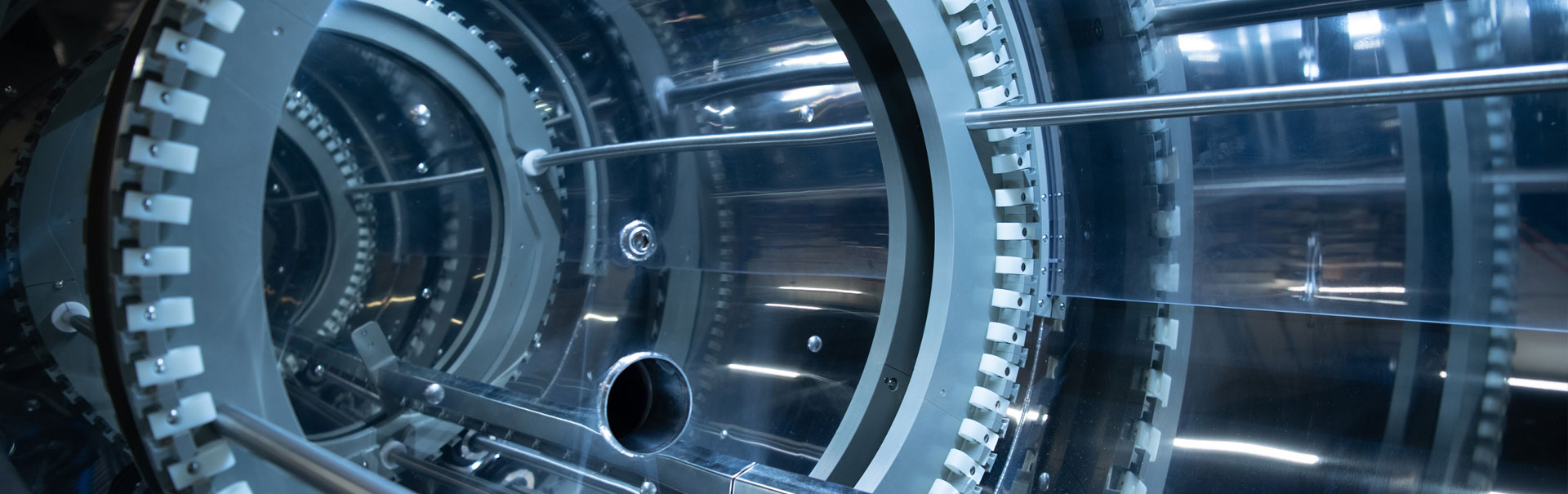

IPS was the first company to offer tablet counters focusing on clean designs and servo technology. Accurate and user friendly, the Procount Slat Counter has been a huge success in the industry. Our liquid fillers featuring peristaltic pumps are also inspired by clean designs and easy changeovers.

Industries we serve

IPS provides the highest quality slats for the most discriminating pharmaceutical manufacturers.

Get Your Quote : (973) 664-0020

Feel free to contact us with any questions or requests for information you may have.